Strip Cutting and Downsetting Process

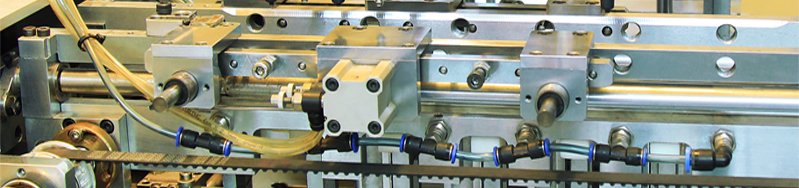

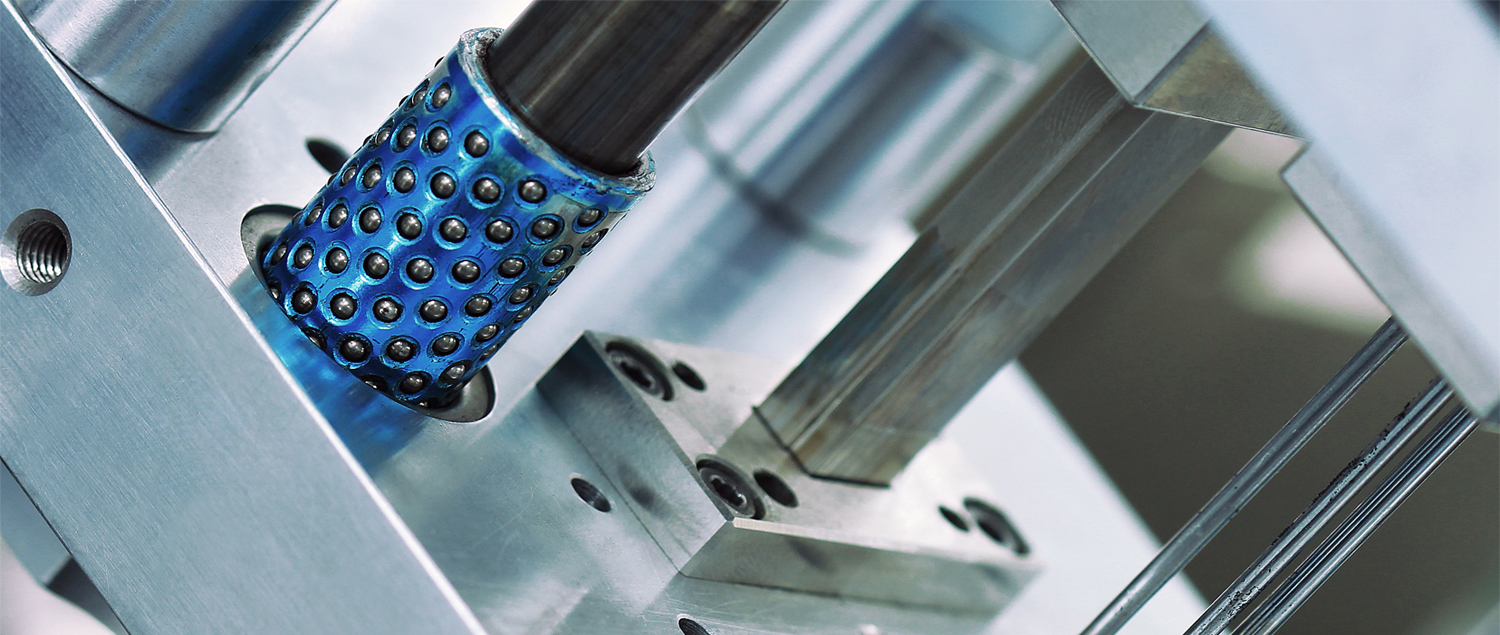

Our backend (cut and downset processes) uses high speed intergrated reel to strip cutting machines. Our cutting machines consist of various tonnage presses ranging from 2 tons to 15 tons. Most of the machines are inco-operated with auto stacking systems to assist running with minimal human contact on plated parts. We are also equipped with 2 custom machines which have capability of auto tape insertion build to customers specific specifications.All our machines are capable to handle deep downset processes with high precision repeatibility quality control specifications.

Our backend cutting team consist of vast experienced personnels who have been exposed to years of relevant industrial experience. This is evident as Amlex was awarded projects and businesses by renowned companies to supply deep downsetting products. This type of projects is to improve exposed die pad outside the mold compound to improve package thermal performance, reduce overall package height and eliminating the need for heat spreaders or heat sinks.

Customers

Customers